While we were moored in the town of Montbard, Kevin mentioned that we should go see La Grande Forge de Buffon. It helps when your captain is an ex-tour guide. We had never heard of La Grande Forge de Buffon, and consequently didn’t know it was only a couple of miles from where we were tied up.

Started in 1768, Georges-Louis Leclerc, Comte de Buffon started his irons works at age sixty. Built on the Armacon River, the plant was considered the height of technology and efficiency. Housing for the workmen and master along with a bakery, kitchen and chapel were all on site. There was even an orangery and dovecote provided to make life easier for the hard working employees. What, you don’t know what an orangery or dovecote is? An orangery is a building with large windows and a heater designed to protect citrus trees during the winter. A dovecote is a structure designed to hold doves and pigeons. A dozen paddle wheels were used to power the forges needed to form the many products produced there.

By the end of the eighteenth century up to 400 workers were turning out 450 tons of iron per year. You can imagine how valuable iron was back then. It took almost one-man year of labor to produce just one ton of iron. When you consider the minimum cost of one workman in a factory including benefits, in this day and age, is at least $50,000 per year. The number is probably closer to $75,000 or even $100,000. It’s hard to believe that there was much demand for iron other than weapons. Buffon used the forge as much for producing iron as a laboratory. He is credited with improving the metallurgy of naval guns.

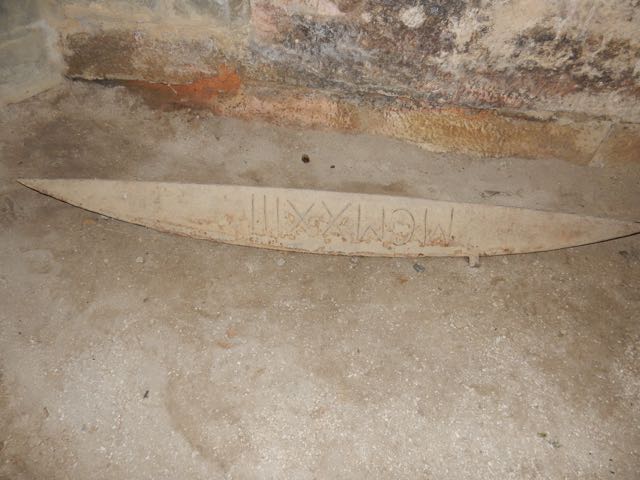

Part of the grand staircase. The orange spot is where the iron was poured into molds dug in the sand.

Wrought iron gates, staircases, and balconies were some of the many products produced at La Grande Forge. Buffon died in 1788, but it wasn’t until 1866 that a great flood destroyed the steel works, and the facility was transformed into a cement factory. Finally in 1923, almost 150 years after La Grande Forge de Buffon was built, it was finally shut down.

You enter the main room via a grand staircase where VIPs could watch the molten iron being poured into molds dug in the sand. There were a number of large pieces of equipment operated by the waterwheels, and used to beat the red-hot iron into shapes that could be used. We even found some resident bats living in one of the back rooms.

-Tom Miller

Author of “The Wave” and “When Stones Speak”– Chuck Palmer Adventure novels

MAR

About the Author:

Tom Miller graduated from the University of Southern California with a Bachelor of Science in Geology. He is a consummate adventurer with over 1,000 dives as a recreational scuba diver, and an avid sailor who has traveled 65,000 miles throughout the Pacific including the Hawaiian Islands. Miller has also cruised the canals of Europe on his canal barge and given numerous lectures on cruising the canals of Europe, as well as sailing in the South Pacific. Piloting is also an interest of Miller's, and He has completed over 1,000 hours flying everything from small Cessnas to Lear jets.